Expert Talk: Maynard Studios' Masterful Railings

These steel stair railings are hand forged, and no two are alike. See how they're made and how they take rooms from plain to breathtaking

After graduating from UC Berkeley, I found myself utterly unprepared for the real world and at a loss as to what I should do next. Luckily, one day I stumbled through the doors of Architectural Digest and was taken under the wing of legendary editor Paige Rense. She had the vision to look past my uninspiring sociology degree and my general lack of experience—an unlikely journalism career was born. After AD, with my magazine karma still intact, I was hired by yet another publishing legend, the food critic and writer Ruth Reichl. I currently ply my trade as a freelance writer and editor and live in stylish Mid-Century-Modern comfort with my dog, Mike. twitter.com/WriteEditDream

It's not easy to be discovered when you're a craftsperson working in a small city in Kentucky. But after being in business for over 12 years, Maynard Studios is finally ready for the spotlight. Matthew and Karine Maynard create hand-crafted metalwork, and their individually designed, hand-forged stair railings are true works of art.

The Maynards' work is always tailored to their clients' vision. "We told ourselves early on that we would never do the same design twice," Matthew says. "No one can point to a picture and say, 'I'll take that one.' Each railing has our handwriting, but it's the client's story."

The following photos highlight some of the couple's projects and outline their work process, which may just inspire you to add artistic elements in unexpected places to your own home.

To find a creative solution for this staircase in Nashville, Tennessee, where the tread width was greater than 5 feet and therefore required a handgrip on both sides, the Maynards approached the wall-mounted portion as an individual railing.

"The newel post was built up in layers and sized to have definite presence in the room, with a large bundle of tapered and twisted-round stock forming the upper portion of the post," explains Karine. "The ribbon drops were placed to allow a grasping point on the lowest tread." Over the years this sort of cascading detail at the start of a newel post has become a style trademark of the Maynards'. Most of the couple's railings are made of steel, which is hand forged and welded, then wire brushed with a clear enamel finish. |

This balcony is perched above a large family room in Nashville and is one section of over 160 feet of railings in the home.

"Sometimes each piece passes through our hands over a dozen times before it's complete," says Karine. "Whether in aluminum, steel, copper or bronze, everything arrives as raw stock. It is then cut to the necessary lengths and sorted." She and Matthew work together to design and make all of the studio's custom pieces. "The heaviest work is done by Matthew," says Karine, "and we have an extra set of hands in the studio now: apprentice and metal sculptor Ben Beckett." |

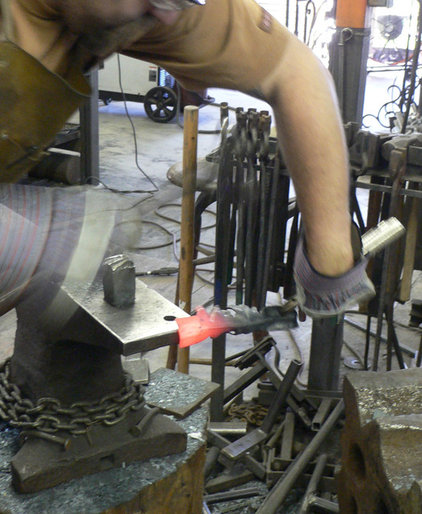

Six components are being put together here to make one piece of a larger railing. Using a hammer, Matthew bends the red-hot metal into the desired shape.

Since they obviously can't touch the hot steel with gloves, they use tongs and clamps to hold the pieces. After a piece is made into its final shape, it's cooled and assembled with the other parts. |

No comments:

Post a Comment